Supply of Industrial Centrifuges

Industries of Application and Types of Supplied Centrifuges

Industries

Centrifuges for enterprises in the following sectors:

- Chemical and Petrochemical Industry — for filtration and dewatering of suspensions, separation of mixtures and reagents;

- Food Industry — for processing sugar, milk, starch, vegetable oils, and beverages;

- Biotechnology — for purification, clarification, and concentration processes;

- Ecology and Energy — for treatment of sludge, wastewater, and waste utilization.

Types

A wide range of industrial centrifuges:

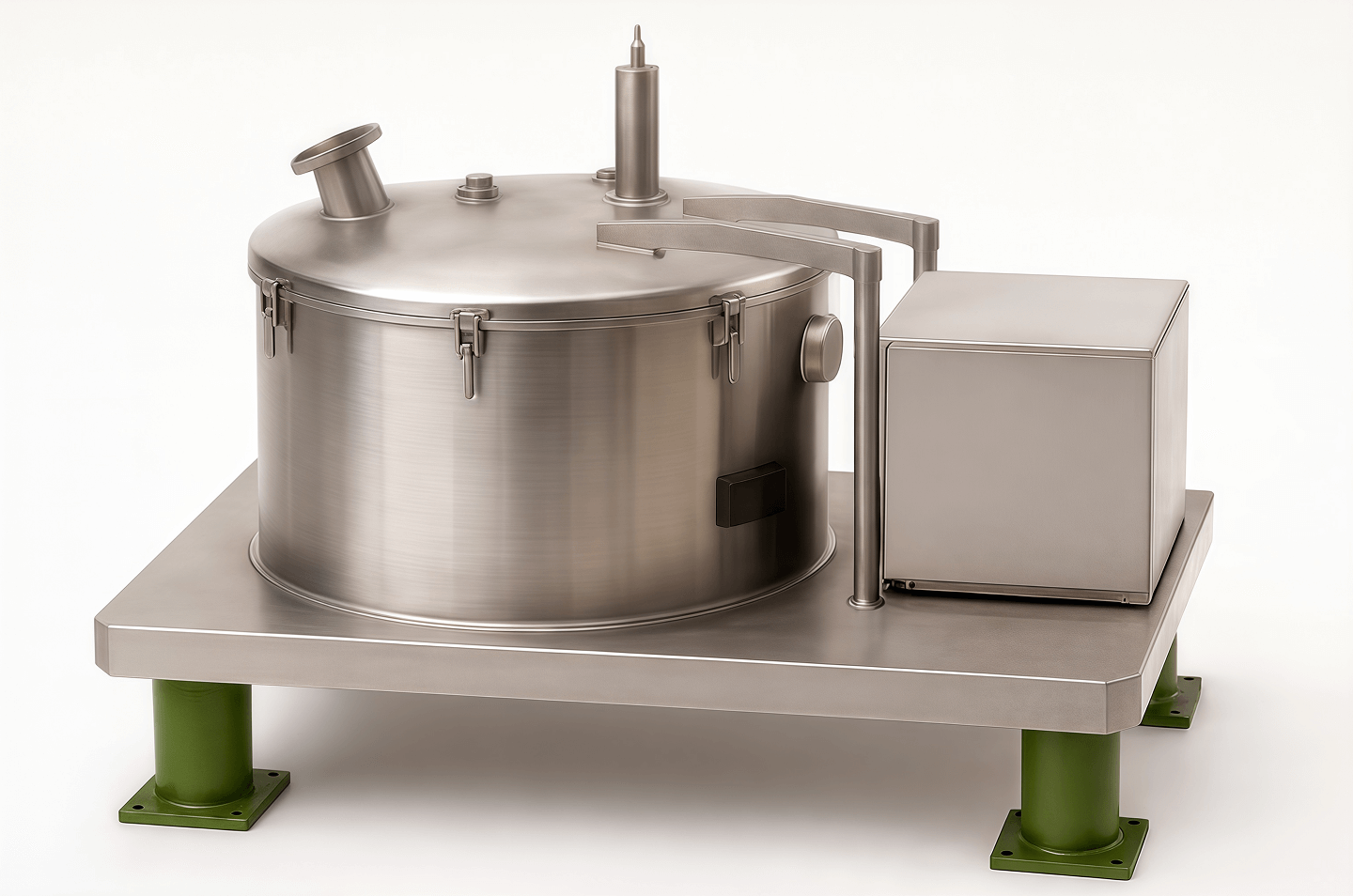

- Filtering and Sedimentation Centrifuges — for efficient solid-liquid separation;

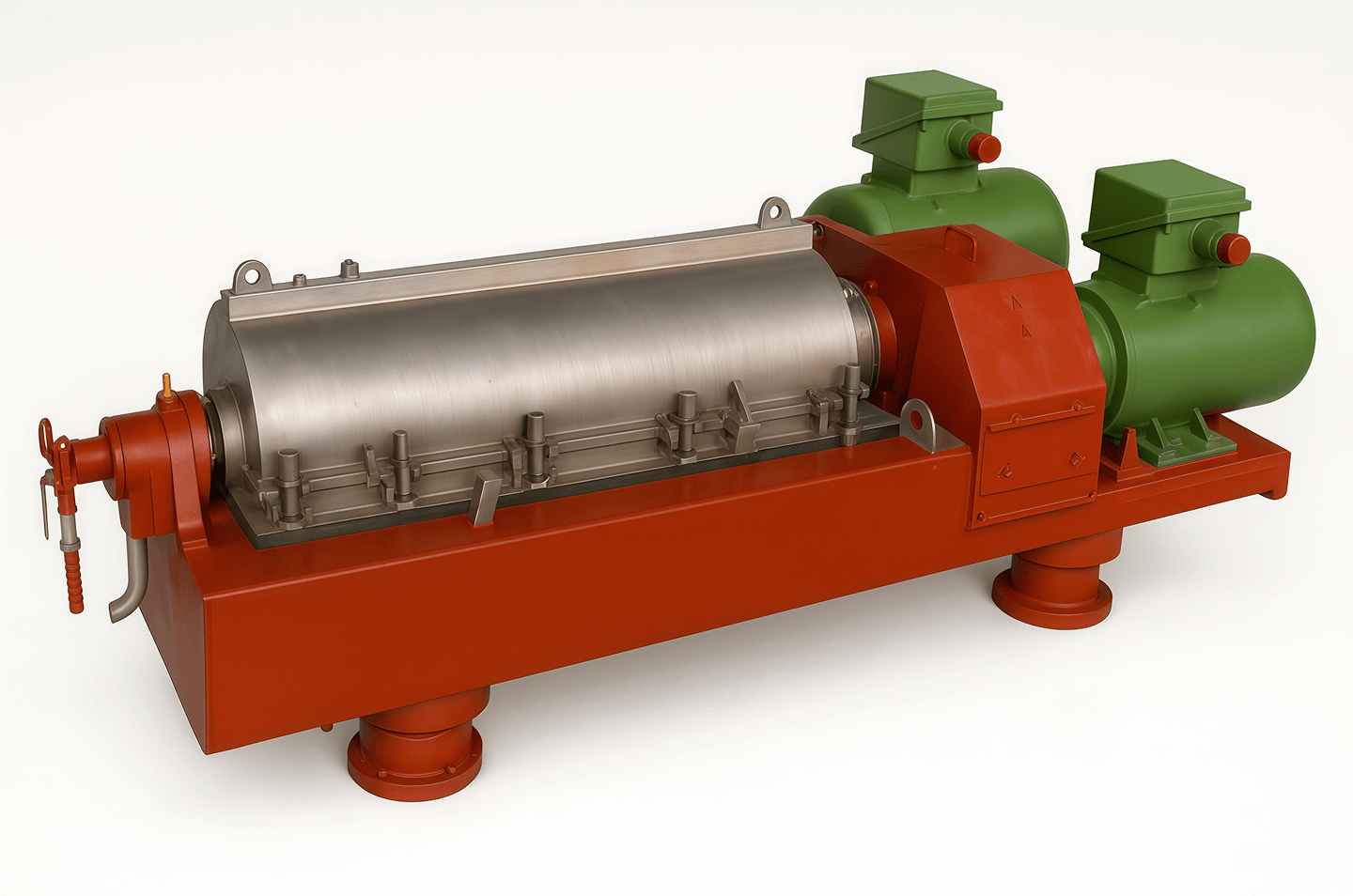

- Decanter Centrifuges — for wastewater treatment, liquid clarification, and suspension concentration;

- Separators and Specialized Models — for technological processes requiring enhanced purity and separation precision;

- Laboratory Centrifuges — for quality control and research purposes.

Each solution is selected considering the technological characteristics of production, product composition, and customer requirements. We provide a comprehensive approach — from engineering equipment selection and design to commissioning and service maintenance.

Technical Specifications

LLC “ZAVKOM-ENGINEERING” offers industrial centrifuges of series T, Y, and C, designed for various types of technological processes.

|

Series |

Cone Angle |

Material Characteristics |

Main Applications |

|

Series T |

8,5 ° |

Used for separating materials with low transparency requirements and high dryness requirements. Can be used with flocculation and reagent dosing. |

Drilling mud, environmental wastewater, oil sludge, cutting fluids, sand washing water, ore washing water, aerated water sludge, saline sludge dewatering, etc. |

|

Series Y |

15 ° |

Used for clarification and drying; suitable for separating high-viscosity materials. |

Mineral oil, chemically viscous materials, fruit juices, coffee, tea, wine, soy milk, leather plant solutions, emulsions, starch, and others. |

|

Series C |

20 ° |

For materials with low concentration requiring high transparency and low dryness. |

Edible oil, protein, lactose, food ingredients, beverage production, oil and water clarification, etc. |

Advantages of Cooperation with LLC “ZAVKOM-ENGINEERING”

- Turnkey Engineering Solutions

We provide a complete range of services — from selection and design of the industrial centrifuge to installation, commissioning, and after-sales service. Thanks to our in-house engineering department and service division, the customer receives a ready-to-operate solution fully integrated into the enterprise’s technological process. - Customized Equipment Selection

Each solution is developed taking into account production specifics, product characteristics, and technological requirements. - Experience and Professionalism

With more than 10 years of experience in industrial engineering, we are capable of executing projects of any complexity — from single-unit equipment supply to full-scale plant outfitting. Our team of engineers, designers, and process specialists controls every stage — from design to commissioning.