APCS – is an automated process control system. The system is a software and hardware complex that solves the problems of abandoning the intellectual labor of the operator by automating the control of technological processes of production.

The main task of APCS – the exclusion of the human factor that leads to errors, downtime and, in rare cases, material damage to production.

ESD system – this is a separate subsystem of the automated process control system. This is emergency protection, which is the last frontier that doesn't allow a person under any circumstances to take actions that will lead to an emergency.

Thus, the automated process control system allows you to reduce risks, improve product quality and eliminate accidents at work.

Receipt or development of technical specifications, specific requirements for process control systems, inspection of the facility and the implementation of research work. The actions list may differ depending on the facility features.

Concept selection and development of the entire control system: this is its structure, reliability, redundancy of critical elements and information security.

This is the control algorithms transfer into program code, the creation of a human-machine interface in a clear and convenient format, and the development of accompanying and design documentation.

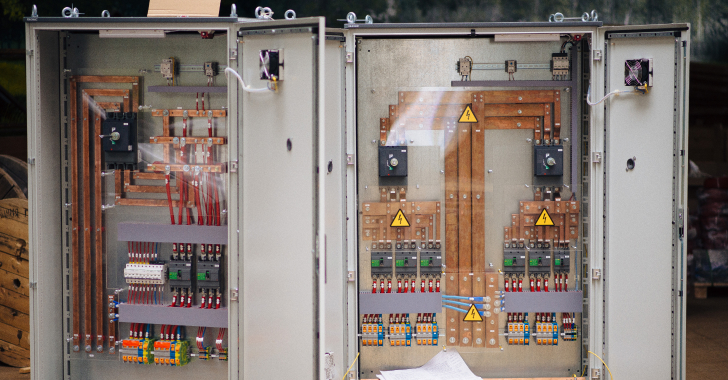

At this stage, control cabinets are assembled, all elements are tested, and FAT (factory acceptance test) is a preliminary delivery of all control algorithms, interlocks and system control at the developer's site.

This is the introduction of APCS at the facility, the repetition of all verification procedures on neutral environments and the output of technological processes at the design indicators.

Working with service personnel, training, testing and trial operation. This can also include warranty support.

Thus, our client does not need to be involved in the process in any way. The result is a system designed to meet all requirements and a well-established technological process.