From September 9 to 11, 2025, at the “EcwaTech” exhibition, we will present vacuum evaporation solutions developed by ZAVKOM-ENGINEERING — a key player in the market for technologies of processing and utilization of industrial waste.

Direct Application: Disposal of Toxic Concentrates

As part of a large-scale environmental project to eliminate accumulated environmental damage and ensure the safety of hydraulic structures, ZAVKOM-ENGINEERING has implemented on a turnkey basis a complex of evaporation units using MVR (Mechanical Vapor Recompression) technology.

These units are designed:

- For concentrating saline and toxic residues;

- For stabilizing the composition of wastewater;

- For reducing the volumes for disposal.

MVR Technology: Energy Efficiency as a Competitive Advantage

Evaporation units with MVR are a solution that combines three key indicators:

- Minimal consumption of boiler steam;

- High reliability in continuous operation;

- Adaptation to complex process streams — including crystallizing and poorly soluble compounds.

All units operate with high heat transfer coefficients and maintain performance even at low temperature gradients — which is critically important for chemically active and energy-balanced processes.

Turnkey Implementation: From Concept to Completed Facility

ZAVKOM-ENGINEERING provides comprehensive supply with execution of all stages:

- Development of design and engineering documentation;

- In-house equipment manufacturing;

- Supply and complete set delivery;

- Installation, supervisory installation, and commissioning on site;

- Personnel training and post-warranty support.

This enables the Customer to control the project life cycle, ensures risk reduction, and provides flexibility in adapting equipment to site requirements.

Capabilities from the Owner and Developer of the Technology

ZAVKOM-ENGINEERING acts not only as a supplier, but also as the developer of licensable technology, which opens up additional opportunities for the Customer:

- Process modification for a specific task, including atypical effluents, space or energy constraints;

- Ensuring technological continuity between stages (evaporation → crystallization → dryer → storage);

- Technology updates and upgrades without dependence on external vendors;

- Reduction of total cost of ownership due to adaptability to changes in feedstock or legislation;

- Flexible support with the possibility of technological outsourcing at the operation stage.

This is especially important in the context of growing regulatory requirements in the field of hazardous waste management and the customers’ drive for import-independent solutions.

Where Our Technology is Applied

Vacuum evaporation technology units from ZAVKOM-ENGINEERING can be effectively integrated into the process operations of enterprises in the following industries:

- Petrochemicals and gas processing;

- Chemical and pharmaceutical industries;

- Processing of industrial and toxic effluents;

- Elimination of accumulated environmental damage objects (onov);

- Production of closed-cycle technical water.

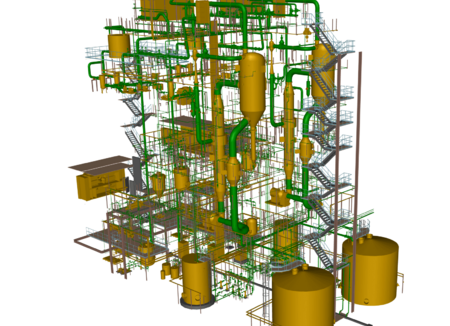

See How It Works

- 3D visualization and principle of operation of the units

- Implementation under actual plant conditions

- New video footage of an operating unit

Where to Discuss the Project and Meet

We invite you to visit the stand of ZAVKOM-ENGINEERING №8F4 at the “EcwaTech 2025” exhibition in Crocus Expo IEC from September 9 to 11, 2025.

At the stand, you will be able to:

- Hold negotiations regarding your project;

- Discuss the technology with our engineers and project team;

- Ask questions about current and implemented solutions.

To plan a meeting and receive additional information about the company’s activities, we recommend using the following links:

- GET A FREE BADGE for exhibition attendance

- SCHEDULE A MEETING AT THE STAND with a specific employee

- MARKETING MATERIALS for “EcwaTech 2025”